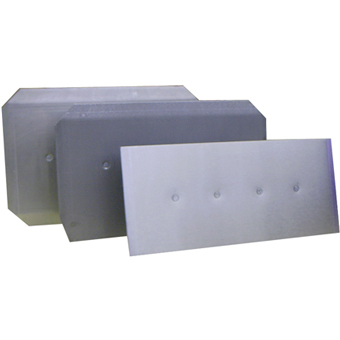

Wacker CT 24-4A Walk-behind Edging Trowel

Edging trowel offers job site solution

Specifically designed for up to the edge finishing, this compact trowel eliminates hand work along walls. This machine improves productivity and quality while providing more ergonomics for the operator. Offering better floating and finishing capabilities along wall lines and obstacles, WACKER’s edging trowel delivers an unmatched solution to the concrete job site.

Features and Benefits CT 24-4A

- Dynamically balanced design for easy and comfortable operation.

- Low vibration handle reduces hand/arm vibration for reduced operator fatigue and increased production.

- Standard foldable handle makes storage convenient while the standard central lifting eye eases transport.

- Ideally suited for concrete finishing up to the edge and around obstacles.

- air-cooled, 4 cycle, single cylinder, Honda gasoline engine.

Technical Data – CT 24-4A

| Description | Metric | Inch |

| Length x width x height (with solid handle) | 1,546 x 610 x 1,041 | mm | 61 X 24 X 41 | in |

| Trowel diameter | 610 | mm | 24 | in |

| Number of blades | 4 |

| Speed range | 90-141 | 1/min | 90-141 | rpm |

| Pitch range | 0-15° | | 0-15° | |

| Engine Type | air-cooled, 4 cycle, single cylinder, gasoline engine,Honda |

| Operating weight | 72,6 |

| Operating speed | 3.800 | 1/min | 3,800 | rpm |

| Piston displacement | 119 | cm3 | 7.3 | in3 |

| Horsepower (at 3600 rpm) | 2,9 |

| Shipping weight | 83 |

| Storage size | 965 x 610 x 867 |

| Shipping size | 978 x 676 x 905 |

| Fuel tank capacity | 2,5 | l | 2.6 | US qt |

| Fuel consumption | 1,3 | l/h | 1.3 | US qt/h |

.

.

.

.

.

.

.

.